Plastic PP PE Film Woven Bag Recycling Washing Line

Our plastic film recycling machine is used to processing the waste plastic such as post consumer plastic bags,PP raffia woven jumbo bags, plastic LDPE agriculture film,greenhouse film, PP PE film, industrial packaging LLDPE film,etc.

Material: Plastic Film / PP PE Woven Bag / Non-woven fabric, raffia etc

Product size: 30-100mm or customized

Moisture content remain: <3%

Applications:

Plastic film recycling washing line is working to reprocessing waste plastic materials like LDPE film agriculture film,LLDPE stretch film,PP woven bag,PP raffia jumbo bags,etc.

Our PP PE film washing line can efficiency clean plastic film and remove the impurities like soil, sand, grease, glue, stickers and other dirt on film. With more than 20 years working on machine design and manufacture, we gained very rich experience on film washing recycling machines. One customer-One film washing line solution is our promise to regular and new customers, all the plastic recycling solutions and film washing production line are customization according to your factory space and unique requirements.

The input processing capacity of our LDPE film washing line ranges from 300kg/hr to 2000kg/hr. The final output capacity, it is very depending on the level of contaminations on PP/PE film. The most washing plants operate perfectly by choosing our standard design of film recycling line, we also offer the specific design of larger output or some stubborn contaminations.

Models:

Models | Capacity | Power | Area | Water |

RM-300 | 300kg/hr | 100kw/hr | 32*4*5m | 3-4 ton/hr |

RM-500 | 500kg/hr | 160kw/hr | 45*5*5m | 5-6 ton/hr |

RM-1000 | 1000kg/hr | 210kw/hr | 60*6*5m | 8-10 ton/hr |

RM-2000 | 2000kg/hr | 260kw/hr | 65*8*5m | 12-15 ton/hr |

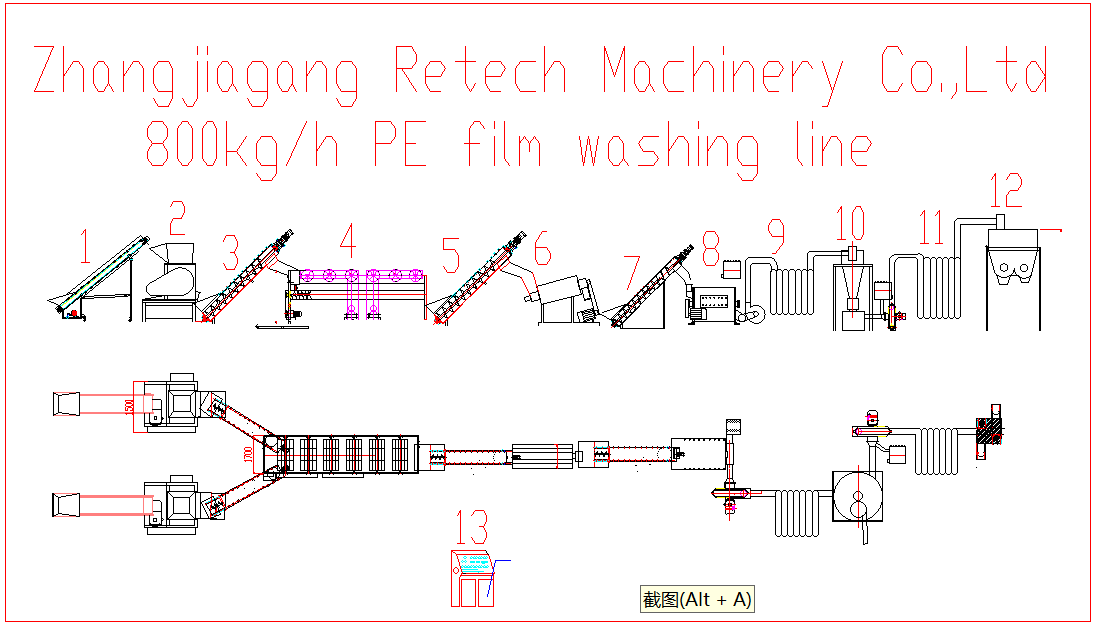

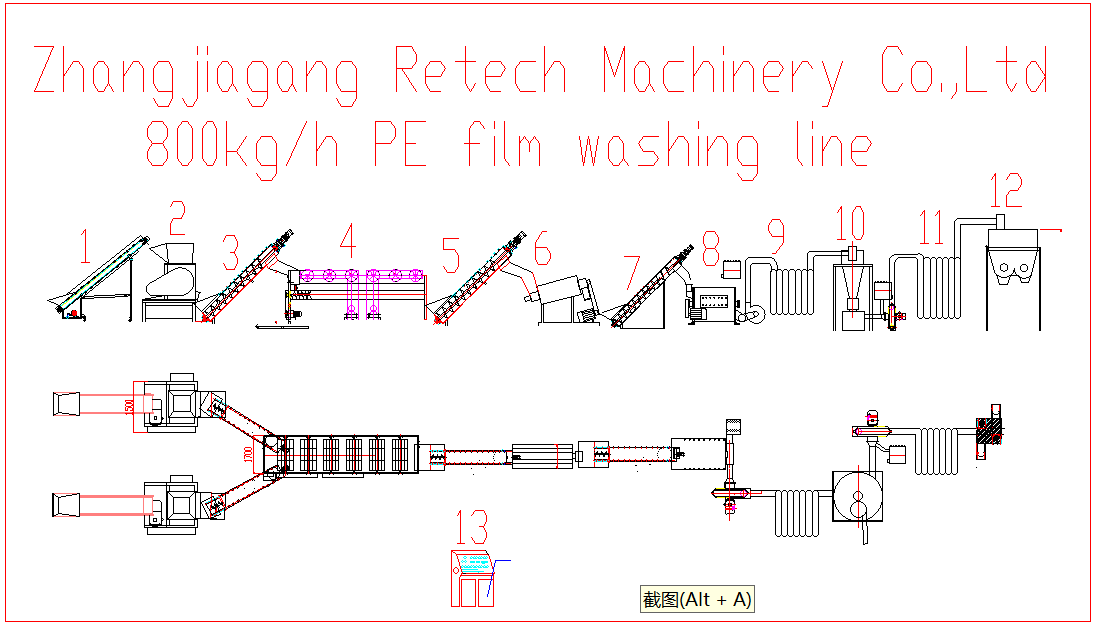

Flowchart of our PP PE film washing line:

Belt conveyor-Wet crusher-high speed friction washer-floating washer-low speed friction washer-floating washer-plastic film squeezer-storage hopper.

Advantages:

1.Our PP(polypropylene) PE(polyethylene) plastic film washing recycling line plant designed and manufactured by Retech team, it is fully automatic running with PLC modular system.

2.By strictly production processing control, we got CE certificate.

3.All the electric elements and key point on machines, we use world brand such as SKF bearing, Siemens motor, ABB inverter, Schneider contactor, D2 blades, etc.

4.The parts that contact with water and material must be stainless steel 304 to make sure the quality of washing line.

5.Providing a circle recycling system including plastic washing and plastic pelletizing. You can have one-stop recycling solution.

6.High quality of washing performance with low humidity around 3%. Final products are clean and dry.

Product description:

1. Heavy duty wet crusher:

The function of plastic crusher is to size reduction the big or long plastic films. Usually crushing with water is much more efficient for improving capacity and pre-washing.

2.High speed friction washer:

To remove the mostly dirt like soil, sand, grease with its centrifugal force, and reduce the washing pressure on floating tank.

3.Floating Sinking density separation washer:

Completely washing the plastic film by water, material swimming and friction with shafts, heavy impurity fall down to water tank, film floating and wash.

4.Centrifuge dryer:

Adopting world famous SKF/NSK bearing for work with fast rotation shaft. The shaft with balance treatment and mesh screen with 3mm hole for drying.

Working together with hot air drying system.

5.Squeezer machine:

Screw squeezing with pressure, electric heating on die cutting system. Making sure the squeezed flakes is very dry within 3% moisture. Automatic squeezing and pelletizing system.